Ever since I built my first “Pi-Hole” with a Raspberry Pi I have had problems with finding good USB cables that will provide enough power. I have also increased my inventory to almost a hundred devices that are powered from a USB connector. The quality of the cable and the length of the cable are huge factors in having reliable device. None of the devices I am using are USB-C Power Delivery compatible which means they are 5V and some of them require 3 amps of current. After trying a number of things my solution is to provide a power supply at the device that can convert 12-24V into 5V with a USB connection. (POE is an option, but at present most of my devices are NOT POE. They are wireless only and just need power source.

There are several pieces to this puzzle that took a lot of time to resolve, like years!

By far the first item I had to find was a low voltage connector.

One day last year I saw this LED connector show up on Amazon. (I’ve bought several hundred of them since.) I have NOT found a competing product! (Yet)

They are NOT perfect!

- I had to figure out how to load the wire into them without damaging the connector.

- It’s actually tricky to get the wire onto all four of the IDC terminals inside it.

- They have a very limited wire size, 22-20 works best.

- They do hold together and I’ve not had an issue with the connection between them.

- I LOVE how small they are and how they have a good “Snap” connection.

The next item was twin lead wire that the connectors could use.

This picture is severely enlarged.

I happened on wire that was used for garage door openers. The wire is normally run to the two sensors at the bottom of the garage door opening.

It’s available in over one-hundred-foot lengths, 20AWG and inexpensive!

Most power supplies also use very similar wire that is clearly marked. (Usually black wire) They are NOT consistent on which wire is positive/negative. For my purposes I chose the dark bar wire as positive since 80% of the power supplies are similarly marked.

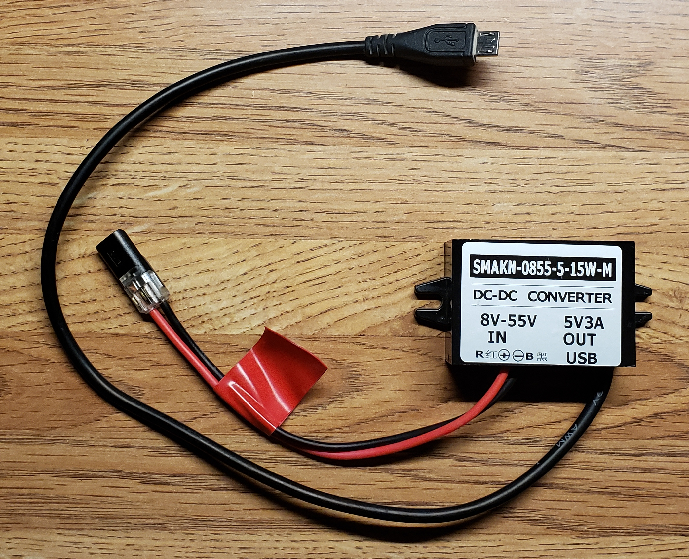

The third component was the USB power supply with connector.

I’ve seen these inexpensive China power supplies for years, but getting the DC to them was the more difficult problem. Now that I have a connector and wire, they are looking much more inviting.

They have varying voltage requirements and most of them provide 3 amps with a very efficient switching power supply which is sufficient for all of the devices I currently have. (They typically do not get warm.) This particular one can take 55Volts which is insane for a 15W load. (A modern golf cart is 56 volts.) The voltage drop at 2A on 100 foot of 20AWG wire is roughly 4 Volts which would still provide 16W (3A@5V) of power. Raising the voltage to 14V drops the current to 1.5A and 18V drops it even further to a little over 1A. Increasing the wire AWG proved to be a worthless venture. (Power supplies are significantly cheaper to change out.)

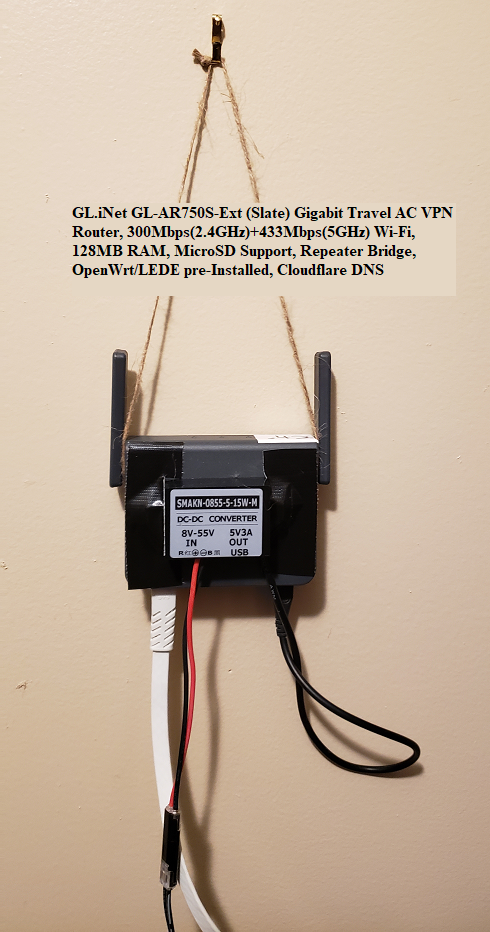

This wireless router can be mounted just about anywhere, and the power requirements are so low that it could be run on one of the 24AWG pairs.